Electronic Science and Technology ›› 2021, Vol. 34 ›› Issue (11): 1-10.doi: 10.16180/j.cnki.issn1007-7820.2021.11.001

XU Yangyang1,SAN Hongjun1,CHEN Jiupeng1,XIE Feiya2,WEI Shunxiang1,WANG Wanglin1,LIU Liang1,CHEN Jia1

Received:2020-07-09

Online:2021-11-15

Published:2021-11-16

Supported by:CLC Number:

XU Yangyang,SAN Hongjun,CHEN Jiupeng,XIE Feiya,WEI Shunxiang,WANG Wanglin,LIU Liang,CHEN Jia. Numerical Simulation Analysis of Temperature Field in LaserCladding of FL-DLight3-4000 Laser[J].Electronic Science and Technology, 2021, 34(11): 1-10.

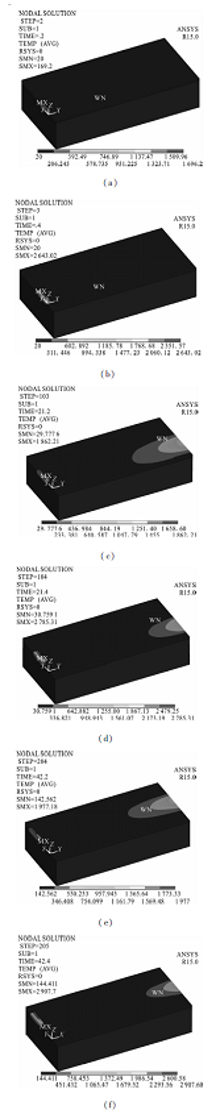

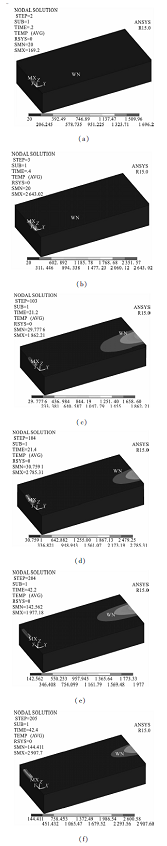

Figure 10.

Temperature field distributions of each cladding layer (a)Temperature field at the beginning of the first cladding layer,(b)Temperature field at the end of the first cladding layer,(c)Temperature field at the beginning of the second cladding layer,(d)Temperature field at the end of the second cladding layer,(e)Temperature field at the beginning of the third cladding layer,(f)Temperature field at the end of the third cladding layer"

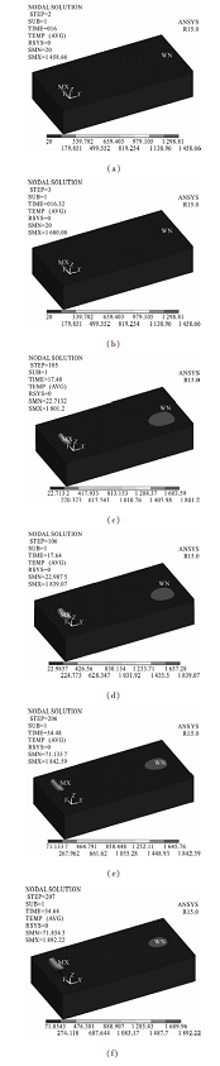

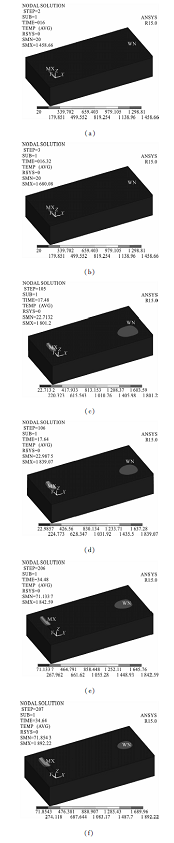

Figure 11.

The temperature field distribution of each cladding layer using the reserved plan (a)Temperature field at the beginning of the first step of the first cladding layer,(b)Temperature field at the beginning of the second step of the first cladding layer,(c)Temperature field at the beginning of the first step of the second cladding layer,(d)Temperature field at the beginning of the second step of the second cladding layer,(e)Temperature field at the beginning of the first step of the third cladding layer,(f)Temperature field at the beginning of the second step of the third cladding layer"

| [1] | 隽永飞, 李军, 蒋云强, 等. 激光熔覆制备高熵合金涂层的研究进展[J]. 应用激光, 2018, 38(1):130-135. |

| Juan Yongfei, Li Jun, Jiang Yunqiang, et al. Research progress of laser cladding for preparing high-entropy alloy coating[J]. Applied Laser, 2018, 38(1):130-135. | |

| [2] | 张瑞珠, 李林杰, 唐明奇, 等. 激光熔覆技术的研究进展[J]. 热处理技术与装备, 2017, 38(3):7-11. |

| Zhang Ruizhu, Li Linjie, Tang Mingqi, et al. Research progress of laser cladding technology[J]. Heat Treatment Technology and Equipment, 2017, 38(3):7-11. | |

| [3] | 孙丽萍, 邹轩, 许伟明. 激光熔覆工艺修复轧辊技术研究[J]. 电子科技, 2015, 28(3):139-147. |

| Sun Liping, Zou Xuan, Xu Weiming. Research of laser cladding repairing technology of roller[J]. Electronic Science and Technology, 2015, 28(3):139-147. | |

| [4] | 赵洪运, 舒凤远, 张洪涛, 等. 基于生死单元的激光熔覆温度场数值模拟[J]. 焊接学报, 2010, 31(5):81-84. |

| Zhao Hongyun, Shu Fengyuan, Zhang Hongtao, et al. Numerical simulation on temperature field of laser cladding based on birth-death element method[J]. Transactions of the China Welding Institution, 2010, 31(5):81-84. | |

| [5] | 徐鹏, 韩一平. 激光辐照材料热效应问题的有限元实现[J]. 电子科技, 2018, 31(3):17-20. |

| Xu Peng, Han Yiping. Finite element method for thermal effect of laser irradiating materials[J]. Electronic Science and Technology, 2018, 31(3):17-20. | |

| [6] | 高东强, 王蕊, 陈威, 等. 激光熔覆改善材料性能的研究进展[J]. 热加工工艺, 2017, 46(12):14-18. |

| Gao Dongqiang, Wang Rui, Chen Wei, et al. Research progress of laser cladding to improve material properties[J]. Hot Working Technology, 2017, 46(12):14-18. | |

| [7] | 刘焜, 陈希章, 徐淑文. 激光熔覆低温相变合金熔覆层的热疲劳性能[J]. 中国表面工程, 2019, 32(3):123-129. |

| Liu Kun, Chen Xizhang, Xu Shuwen. Thermal fatigue properties of laser cladding low temperature phase change alloy cladding[J]. China Surface Engineering, 2019, 32(3):123-129. | |

| [8] | 方金祥, 王玉江, 董世运, 等. 激光熔覆Inconel718合金涂层与基体界面的组织及力学性能[J]. 中国机械工程, 2019, 30(17):2108-2113. |

| Fang Jinxiang, Wang Yujiang, Dong Shiyun, et al. Microstructure and mechanics properties of interfaces between laser cladded inconel718 coating and substrate[J]. China Mechanical Engineering, 2019, 30(17):2108-2113. | |

| [9] | 刘军. 基于不同光斑激光熔覆的数值模拟及试验研究[D]. 杭州:浙江工业大学, 2016. |

| Liu Jun. Numerical simulation and experimental study on laser cladding with different spot[D]. Hangzhou:Zhejiang University of Technology, 2016. | |

| [10] | 林程, 狄姣, 车显飞, 等. 激光熔覆涂层的研究现状[J]. 中国陶瓷, 2017, 53(4):1-6. |

| Lin Cheng, Di Jiao, Che Xianfei, et al. Research status of laser cladding coating[J]. Chinese Ceramics, 2017, 53(4):1-6. | |

| [11] | 仇卫华. 激光表面强化中温度场与热应力场的数值模拟与分析[D]. 南京:南京航空航天大学, 2008. |

| Qiu Weihua. Numerical simulation and analysis of temperature field and thermal stress field in laser surface hardening[J]. Nanjing:Nanjing University of Aeronautics and Astronautics, 2008. | |

| [12] | 杨贤群, 赵洪运, 姜秋月, 等. 送粉式激光熔覆温度场有限元分析[J]. 热加工工艺, 2007, 36(23):79-81. |

| Yang Xianqun, Zhao Hongyun, Jiang Qiuyue, et al. Finite element analysis of temperature field of powder feeding laser cladding[J]. Hot Working Technology, 2007, 36(23):79-81. | |

| [13] | 张佳丽. 激光熔覆技术的温度场数值模拟分析[D]. 乌鲁木齐:新疆大学, 2019. |

| Zhang Jiali. Numerical simulation of temperature field of laser cladding technology analysis[D]. Urumqi:Xinjiang University, 2019. | |

| [14] | 赵海玲. 激光熔覆熔池温度场和流场的数值模拟[D]. 秦皇岛:燕山大学, 2013. |

| Zhao Hailing. Numerical simulation of temperature field and flow field during laser cladding molten pool[D]. Qinhuangdao:Yanshan University, 2013. | |

| [15] | 李豪, 王彦芳, 石志强, 等. 基于椭圆热源模型的激光熔覆温度场与流场数值模拟[J]. 应用激光, 2017, 37(2):218-222. |

| Li Hao, Wang Yanfang, Shi Zhiqiang, et al. Numerical simulation of temperature and flow fields in laser cladding based on ellipse heat source model[J]. Applied Laser, 2017, 37(2):218-222. | |

| [16] | 郝南海, 陆伟, 左铁钏. 激光熔覆过程热力耦合有限元温度场分析[J]. 中国表面工程, 2004, 17(6):10-14. |

| Hao Nanhai, Lu Wei, Zuo Tiechuan. Thermal-mechanical coupled finite element temperature field analysis of laser cladding process[J]. China Surface Engineering, 2004, 17(6):10-14. | |

| [17] | 刘昊, 虞钢, 何秀丽, 等. 送粉式激光熔覆中瞬态温度场与几何形貌的三维数值模拟[J]. 中国激光, 2013, 40(12):84-91. |

| Liu Hao, Yu Gang, He Xiuli, et al. Three-dimensional numerical simulation of transient temperature field and geometry in powder-feed laser cladding[J]. China Journal of Laser, 2013, 40(12):84-91. | |

| [18] | 胡围围, 马继宇, 康进武, 等. 激光多层熔覆成形温度场数值模拟和工艺优化[J]. 热加工工艺, 2009, 38(7):136-139. |

| Hu Weiwei, Ma Jiyu, Kang Jinwu, et al. Numerical simulation and process optimization of temperature field in laser multilayer cladding forming[J]. Hot Working Technology, 2009, 38(7):136-139. |