Electronic Science and Technology ›› 2023, Vol. 36 ›› Issue (11): 41-46.doi: 10.16180/j.cnki.issn1007-7820.2023.11.007

Previous Articles Next Articles

QIAN Dingdong,SONG Ke,WANG Wei

Received:2022-06-27

Online:2023-11-15

Published:2023-11-20

Supported by:CLC Number:

QIAN Dingdong,SONG Ke,WANG Wei. Research on Internal Positioning of Transformer Partial Discharge Ultrasound Based on Whale Algorithm[J].Electronic Science and Technology, 2023, 36(11): 41-46.

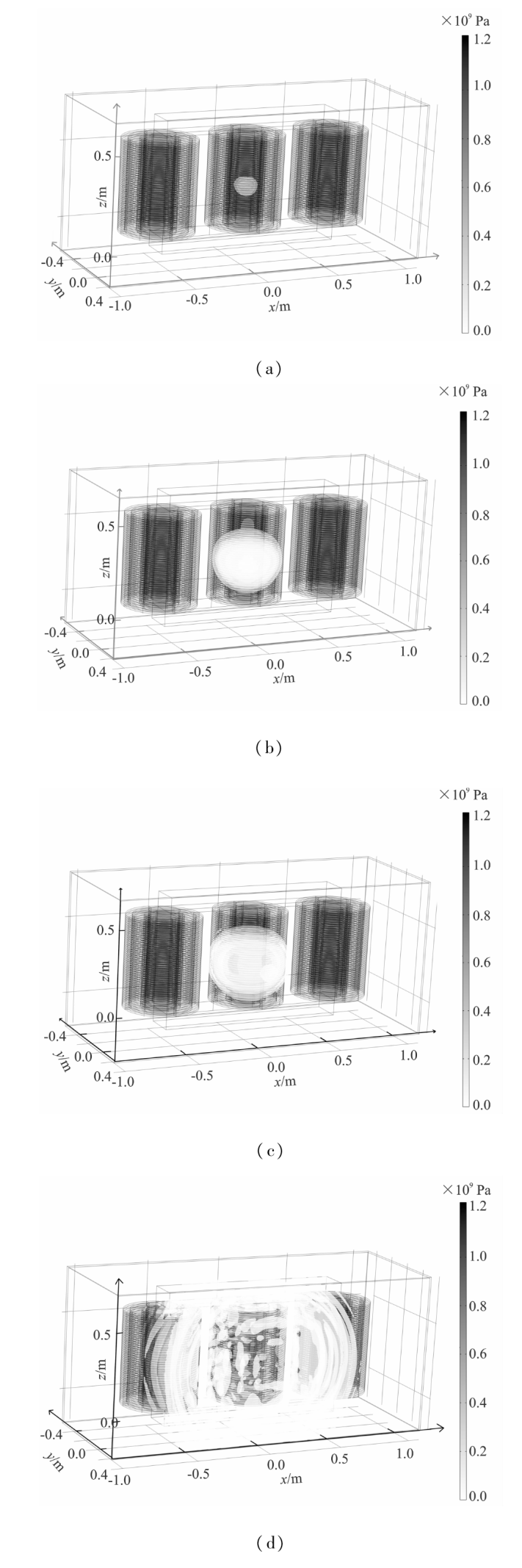

Figure 2.

Example of spatial sound pressure distribution generated by partial discharge source (a)Sound pressure distribution after 50 μs of partial discharge point (b)Sound pressure distribution after 150 μs of partial discharge point (c)Sound pressure distribution after 200 μs of partial discharge point (d)Sound pressure distribution after 500 μs of partial discharge point"

Table 2.

B-phase symmetrical quadrilateral WOA algorithm positioning error"

| 点 | 局放源坐标/m | 定位坐标/m | 误差/cm |

|---|---|---|---|

| M | 0.170,0.170,0.500 | 0.162,0.168,0.553 | 5.40 |

| M | 0.170,0.170,0.300 | 0.155,0.188,0.298 | 2.35 |

| M | 0.170,0.170,0.100 | 0.196,0.198,0.106 | 3.87 |

| N | 0.115,-0.048,0.485 | 0.188,-0.070,0.485 | 7.62 |

| N | 0.115,-0.048,0.285 | 0.119,-0.047,0.369 | 8.14 |

| N | 0.115,-0.048,0.150 | 0.139,-0.056,0.171 | 3.29 |

Table 3.

B-phase asymmetric quadrilateral WOA algorithm positioning error"

| 点 | 局放源坐标/m | 定位坐标/m | 误差/cm |

|---|---|---|---|

| M | 0.170,0.170,0.500 | 0.178,0.186,0.479 | 2.76 |

| M | 0.170,0.170,0.300 | 0.174,0.189,0.333 | 3.83 |

| M | 0.170,0.170,0.100 | 0.204,0.198,0.096 | 4.42 |

| N | 0.115,-0.048,0.485 | 0.143,-0.093,0.454 | 6.14 |

| N | 0.115,-0.048,0.285 | 0.132,-0.058,0.272 | 2.36 |

| N | 0.115,-0.048,0.150 | 0.119,0.055,0.114 | 3.69 |

Table 4.

Positioning error of WOA algorithm for partial discharge point of phase A"

| 点 | 局放源坐标/m | 定位坐标/m | 误差/cm |

|---|---|---|---|

| Q | 0.10,0.67,0.15 | 0.157,0.624,0.131 | 7.60 |

| Q | 0.10,0.67,0.35 | 0.077,0.660,0.309 | 4.81 |

| Q | 0.10,0.67,0.55 | 0.137,0.634,0.575 | 4.28 |

| P | 0.18,0.75,0.05 | 0.213,0.718,0.042 | 4.67 |

| P | 0.18,0.75,0.25 | 0.207,0.724,0.225 | 4.51 |

| P | 0.18,0.75,0.40 | 0.189,0.721,0.360 | 4.86 |

| [1] | 卓晓冬. 电气设备绝缘系统局部放电检测技术研究[J]. 电子科技, 2019, 32(11):83-86. |

| Zhuo Xiaodong. Research on partial discharge detection technology of electrical equipment insulation system[J]. Electronic Science and Technology, 2019, 32(11):83-86. | |

| [2] | 高国磊, 李英娜, 段效琛, 等. 基于ACO优化LS-SVM的变压器故障诊断[J]. 电子科技, 2018, 31(6):59-62,74. |

| Gao Guolei, Li Yingna, Duan Xiaochen, et al. A fault diagnosis method for transformer based on least squares support vector machine optimized by ant colony optimization[J]. Electronic Science and Technology, 2018, 31(6):59-62,74. | |

| [3] | 周秀, 吴旭涛, 汲胜昌, 等. 基于空间电容耦合原理的局部放电检测方法及其传感器研究[J]. 高压电器, 2022, 58(4):63-69. |

| Zhou Xiu, Wu Xutao, Ji Shengchang, et al. Study on partial discharge detection method and sensor based on principle of space capacitive coupling[J]. High Voltage Apparatus, 2022, 58(4):63-69. | |

| [4] | 张兴辉, 常文治, 杜非, 等. GIS局部放电多特征量传感研究进展[J]. 高压电器, 2022, 58(4):8-16. |

| Zhang Xinghui, Chang Wenzhi, Du Fei, et al. Research progress of multi-physics sensing in partial discharge of GIS[J]. High Voltage Apparatus, 2022, 58(4):8-16. | |

| [5] | 杨玥坪, 树婷, 吴玖汕, 等. 变压器绕组局部放电量测量误差计算及其修正方法研究[J]. 西安交通大学学报, 2022(10):1-7. |

| Yang Yueping, Shu Ting, Wu Jiushan, et al. Error analysis and correction of partial discharge quantity measurement of transformer windings[J]. Journal of Xi'an Jiaotong University, 2022(10):1-7. | |

| [6] | 佘昌佳, 郑建勇, 何嘉弘, 等. 时差筛选和ABC二次寻优的变压器局放超声定位方法[J]. 高电压技术, 2021, 47(8):2820-2827. |

| She Changjia, Zheng Jianyong, He Jiahong, et al. Ultrasonic localization method of transformer partial discharge by time difference screening and ABC secondary optimization[J]. High Voltage Engineering, 2021, 47(8):2820-2827. | |

| [7] | 倪鹤立, 姚维强, 傅晨钊, 等. 电力设备局部放电技术标准现状述评[J]. 高压电器, 2022, 58(3):1-15. |

| Ni Heli, Yao Weiqiang, Fu Chenzhao, et al. Review on status of technical standards of partial discharge in electrical equipment[J]. High Voltage Apparatus, 2022, 58(3):1-15. | |

| [8] | 杨尚霄. 牵引变压器故障诊断方法综述[J]. 电子测量技术, 2021, 44(4):110-117. |

| Yang Shangxiao. A review of fault diagnosis methods for traction transformers[J]. Electronic Measurement Technology, 2021, 44(4):110-117. | |

| [9] | 刘铟. 局部放电故障特征提取的方法研究[D]. 北京: 华北电力大学, 2021:30-35. |

| Liu Yin. Research on method of partial discharge fault feature extraction[D]. Beijing: North China Electric Power University, 2021:30-35. | |

| [10] | Almasri W M F, Abdelhafez M F, Elhag A H. A novel bias detection technique for partial discharge localization in oil insulation system[J]. IEEE Transactions on Instrumentation & Measurement, 2016, 65(2):448-457. |

| [11] |

Ghosh R, Chatterjee B, Dalai S. A method for the localization of partial discharge sources using partial discharge pulse information from acoustic emissions[J]. IEEE Transactions on Dielectrics and Electrical Insulation, 2017, 24(1):237-245.

doi: 10.1109/TDEI.2016.006080 |

| [12] | 彭炜文, 刘伟杰, 许家浩, 等. 一种基于相关系数的EEMD局部放电去噪方法[J]. 高压电器, 2021, 57(6):203-209. |

| Peng Weiwen, Liu Weijie, Xu Jiahao, et al. EEMD partial discharge de-noising method based on correlation coefficients[J]. High Voltage Apparatus, 2021, 57(6):203-209. | |

| [13] |

Goyal S, Bhushan S, Kumar Y, et al. An optimized framework for energy-resource allocation in a cloud environment based on the whale optimization algorithm[J]. Sensors, 2021, 21(5):1583-1583.

doi: 10.3390/s21051583 |

| [14] | 李玲玲, 王鑫, 郎永波, 等. 基于改进鲸鱼算法的微网复合储能系统容量优化配置[J]. 电测与仪表, 2019, 56(16):104-110. |

| Li Lingling, Wang Xin, Lang Yongbo, et al. Capacity configuration of micro-grid composite energy storage system based on improved whale optimization algorithm[J]. Electrical Measurement & Instrumentation, 2019, 56(16):104-110. | |

| [15] | 左兴喜. 变压器局部放电多目标定位方法的研究[D]. 重庆: 重庆理工大学, 2020:15-17. |

| Zuo Xingxi. Study on multi-object localization method of partial discharge in transformer[D]. Chongqing: Chongqing University of Technology, 2020:15-17. | |

| [16] | 王鹏. 变压器局放超声阵列传感器指向性评价[D]. 北京: 华北电力大学, 2019:27-40. |

| Wang Peng. Directivity evaluation of transformer partial discharge ultrasonic array sensor[D]. Beijing: North China Electric Power University, 2019:27-40. | |

| [17] | Wotzka D, Boczar T, Zmarzly D. Analysis of acoustic wave propagation in a power transformer model[J]. Acta Physica Polonicaa, 2009, 116(3):428-431. |

| [18] | 卢雪琴, 李长安, 吴忠强. 基于鲸鱼算法优化极限学习机的微电网故障诊断[J]. 智慧电力, 2022, 50(2):15-21. |

| Lu Xueqin, Li Changan, Wu Zhongqiang. Microgrid fault diagnosis based on extreme learning machine optimized by whale algorithm[J]. Smart Power, 2022, 50(2):15-21. | |

| [19] | 柴源. 基于改进鲸鱼算法的风-光-重力储能系统优化配置研究[D]. 西安: 西安理工大学, 2021:32-38. |

| Chai Yuan. Study on optimal configuration of wind power-photovoltaic-gravity energy storage system based on improved whale algorithm[D]. Xi'an: Xi'an University of Technology, 2021:32-38. |

| [1] | XU Lili,YANG Chao,ZENG Haoran. Fault Section Location of Distribution Network with DG Based on Improved Whale Algorithm [J]. Electronic Science and Technology, 2023, 36(1): 15-20. |

| [2] | SUN Kang,XUAN Xuyang,LIU Penghui,ZHAO Laijun,LONG Jie. Partial Discharge Pattern Recognition of Cable Based on CNN-DCGAN under Small Data [J]. Electronic Science and Technology, 2022, 35(7): 7-13. |

| [3] | YANG Yunhui,XU Lianjiang. Summary of Finite Element Analysis Technology for High Precision Machining [J]. Electronic Science and Technology, 2022, 35(11): 98-103. |

| [4] | LIU Yaze,ZHANG Shuai,GUO Liang,CHEN Xintong,WU Jiankang. Simulation Analysis of Induced Current Density of Transcranial Magnetic-Acoustical Electrical Stimulation Based on Realistic Human Head Model [J]. Electronic Science and Technology, 2021, 34(6): 17-22. |

| [5] | FANG Xin,WU Yaohui,SONG He. Electromagnetic Simulation Analysis of Asynchronous Motor Starting [J]. Electronic Science and Technology, 2021, 34(6): 61-66. |

| [6] | SAN Hongjun, LI Pengyu, CHEN Jiupeng, HU Qiongqiong, LI Qi, ZHANG Kaixiang, WANG Chen. A Design and Optimization Analysis of the Centered Positioning Mechanism [J]. Electronic Science and Technology, 2021, 34(1): 10-16. |

| [7] | CHEN Yu,CHEN Long. Isogeometric Analysis of Complex Planar Porous Model [J]. Electronic Science and Technology, 2020, 33(5): 38-44. |

| [8] | LIU Zhuli,WANG Xudong,XU Xiaozhuo,JI Shengyang,FAN Lele. Effect of Slot Wedge Material on Electromagnetic Characteristics of PMLSM [J]. Electronic Science and Technology, 2020, 33(11): 73-78. |

| [9] | WANG Yang,LI Yingna,LI Chuan. Analysis on Electric Field and Electrodynamics Force of Switching Air-core Reactor [J]. Electronic Science and Technology, 2019, 32(3): 47-52. |

| [10] | ZHUO Xiaodong. Research on Partial Discharge Detection Technology of Electrical Equipment Insulation System [J]. Electronic Science and Technology, 2019, 32(11): 83-86. |

| [11] | ZHAO Hui,JIN Hai. Direct Instantaneous Torque Control of Switched Reluctance Motor Based on Fuzzy Self-tuning PI [J]. Electronic Science and Technology, 2019, 32(11): 58-63. |

| [12] | XU Feng, HAN Yi-Beng. Finite Element Method for Thermal Effect of Laser Irradiating Materials [J]. , 2018, 31(3): 17-. |

| [13] | FENG Yanglei,SHEN Jingfeng. Structural Optimization Analysis of Approximate Middle Channel Plate [J]. , 2017, 30(9): 149-. |

| [14] | SUN Yi 1,CHU Chaomei 1,GU Jianhua 2. Simulation of Thermal Load of the Dual Clutches of Dual Clutch Transmission [J]. , 2017, 30(4): 64-. |

| [15] | QIU Bowen,LI Haolin. Applications of Hyperworks in Dynamic and Static Analysis of Machine Tool Bed [J]. , 2016, 29(3): 25-. |

|